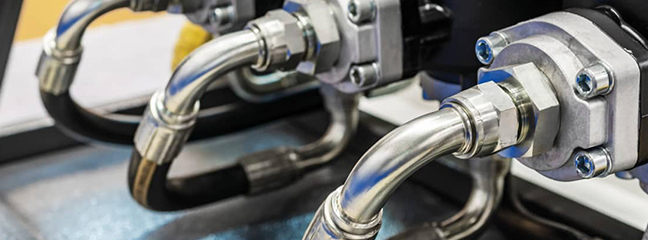

At Heshun Machinery, we understand the manufacturer’s requirements for the accuracy and adaptability of the pipe bending process. This is why we customized the HSB-38 NC single-head semi-automatic pipe bender to meet the specific needs of small and medium-sized production operations. By combining intuitive control with powerful electro-hydraulic drive, this model offers reliable and complex bending – from furniture handrails to automotive exhaust components – while minimizing setup time and material waste.

The HSB-38 NC of Heshun Machinery can accommodate pipes with a diameter of up to 38 millimeters, and achieve smooth bending from 0 to 190 degrees under precise CNC. Thanks to the electro-hydraulic hybrid drive, with a hydraulic stability of up to 14 MPa, our customers benefit from an Angle accuracy of ±1° and a position repeatability of ± 0.1mm. This makes it strong enough to perform rigorous bending tasks and also very suitable for moderate workshops.

Our version of the HSB-38 NC elevates operator experience through a multilingual LCD touchscreen interface, available in both English and Chinese. Technicians simply enter bend angles and feed/rotation commands, and the integrated PLC/NC logic orchestrates the bending head’s motions. Manual feeding and rotation streamline changeovers, eliminating the complexity of fully automated positioning systems yet still preserving the flexibility to handle a wide array of tooling options—whether forming dies, mandrel supports, or mandrel-less configurations. The mandrel and anti-wrinkle die ensure that products with thin wall thickness and small bending radius are less likely to wrinkle

Heshun Machinery’s HSB-38 NC is engineered to bend a wide spectrum of materials, from carbon and stainless steel to aluminum, copper, and brass, including round, square, rectangular, and custom-profile tubes. This material versatility makes our machine the first choice for industries such as furniture manufacturing—where elegant curves define handrails and chair frames—architectural design, where decorative piping demands both form and function, and automotive or heat-exchange systems, where precision bends in exhaust manifolds and piping assemblies are critical. Across all these applications, the HSB-38 NC consistently demonstrates its value in mid-volume, high-precision contexts.

The HSB-38 NC series embodies this commitment, providing consistent complex elbows for a wide range of industries and batch sizes. We sincerely invite you to contact us immediately to discuss how our customized HSB-38 pipe bending machine with numerical control system can change your production process, improve your product quality and drive your business forward.

When you choose Heshun Machinery, you’re not just purchasing a machine; you are gaining a manufacturing partner. The price of our machines depends on the material, wall thickness, pipe diameter, bending Angle and bending radius of the pipes to be processed. We provide turnkey tooling solutions customized to your tube diameters and bend radii, along with comprehensive after-sales support, on-site installation, and operator training to ensure your team achieves peak productivity from day one. With the development of production demands, we can also provide corresponding fully automatic servo pipe benders according to your specific needs.

When you choose Heshun Machinery, you’re not just purchasing a machine; you are gaining a manufacturing partner. The price of our machines depends on the material, wall thickness, pipe diameter, bending Angle and bending radius of the pipes to be processed. We provide turnkey tooling solutions customized to your tube diameters and bend radii, along with comprehensive after-sales support, on-site installation, and operator training to ensure your team achieves peak productivity from day one. With the development of production demands, we can also provide corresponding fully automatic servo pipe benders according to your specific needs.

Heshun Machinery specializes in providing high-precision custom tube bending and forming solutions for a wide range of industries around the world.

No.299,Fumin Road,Tangqiao Town,Zhangjiagang,China

0512-58622076

heshunchenyi@163.com

Copyright © Leading Tube Bending & Forming Machines Manufacturer all rights reserved.