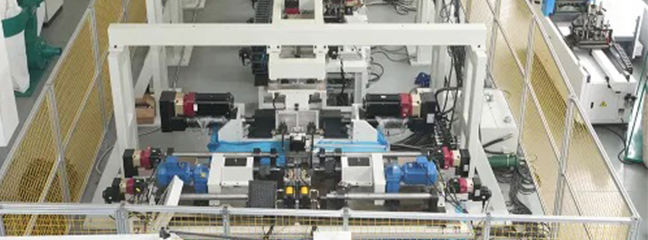

Bend Beyond Limits: Heshun’s Custom HSB-38 NC Solution

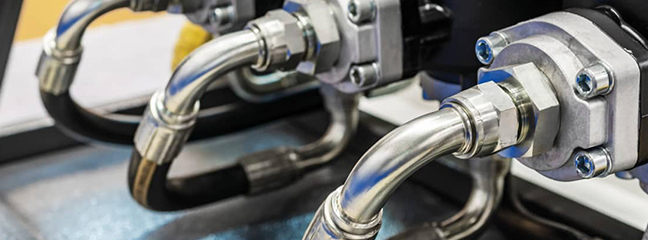

At Heshun Machinery, we understand the manufacturer’s requirements for the accuracy and adaptability of the pipe bending process. This is why we customized the HSB-38 NC single-head semi-automatic pipe bender to meet the specific needs of small and medium-sized production operations. By combining intuitive control with powerful electro-hydraulic drive, this model offers reliable and complex bending – from furniture handrails to automotive exhaust components – while minimizing setup time and material waste.