As a professional CNC tube bending machine supplier, Heshun Machinery is committed to producing four different types of tube bending machines with excellent performance,

with a wide range of bending capacity of 0-190°, applicable to a variety of tube sizes, can be high-precision bending of stainless steel, carbon steel, brass, bronze and other metal materials, strong adaptability.

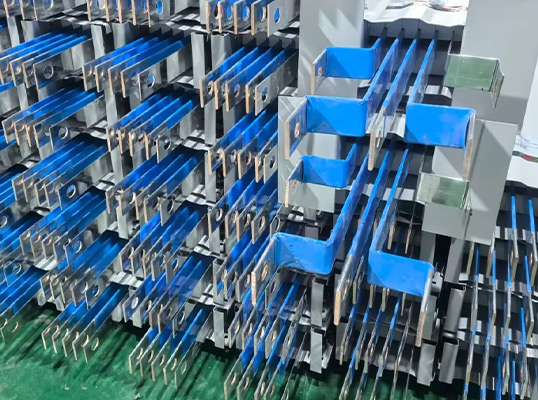

The pipe bending machine supports single-layer die, double-layer die and multi-layer die bending function, which can efficiently deal with round, square, rectangular and other pipe types to meet the diverse processing needs.

As a professional supplier of CNC tube end forming machines, Heshun Machinery offers a full range of machines capable of performing tube expansion, tube reduction, flaring, crimping, and other tube end forming processes with

exceptional precision. Whether it's a standard tube end shape or a completely custom design, we have a solution to meet your production needs.

Each of our pipe bending and tube end forming machines is rigorously tested and precision manufactured to provide you with maximum convenience on the subject of pipe bending.

Whether it is the most basic machines or customized needs, we can provide solutions to meet your needs, and comprehensively help to enhance market competitiveness.

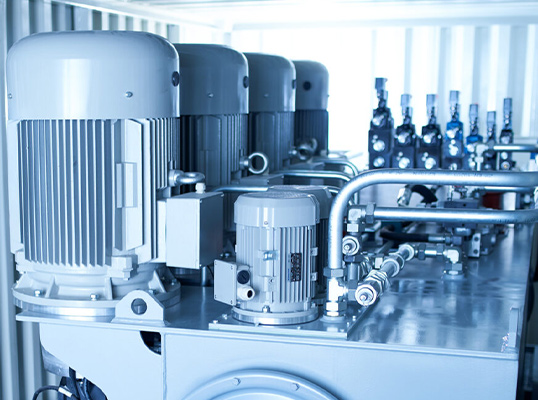

Accurate, High-speed, Stable Bending Technology

For Copper, Aluminum, Iron, Steel And A Wide Range Of Metals

Provides Maximum Flexibility For Multi-industry Precision Bending

Customized Machines For

Specific Requirements

With its excellent stability and high-precision performance, it helps global customers improve production efficiency and achieve rapid prototyping of complex pipe bending structures.

Heshun Machinery not only provides high-performance pipe bending machine equipment, but also high-tech processes suitable for small to large-scale production. Whether it is complex pipe fittings, one-piece molding, or flexible manufacturing, we can provide you with efficient and stable bending solutions.

Custom bending solutions for Φ10-200mm tubes in stainless steel/carbon steel/alloy steel. Cold bending/hot push forming with ±0.1mm tolerance, wrinkle rate <0.5%. Free 3D drawing optimization included.

Solving 0.5mm ultra-thin stainless tube bending wrinkles! CNC servo-controlled benders + custom anti-wrinkle dies achieve ≤0.3% wrinkle rate. Integrated 3D laser scanners correct ovality in real-time for medical/aerospace precision tubing.

CNC programming + hydraulic die maintenance.Custom anti-wrinkle dies/mandrels available. Extends equipment lifespan by 30%+.

Where do high-quality products come from:they come from strict quality control of raw materials at first,then scientifc production processes, sophisticated process control and also quality inspection in place.

Want to know more about our brand story and technical background?

Contact Us