Description

Application Areas

Automotive

Specializing in the production of automotive exhaust systems, chassis parts and other core components

HVAC

Used for precision bending of central air conditioning and ventilation system pipes

Furniture Manufacturing

Tube bending for metal furniture frames, decorative parts and other crafts

Aerospace

Ultra-high precision is used to achieve aircraft fluid management, engine piping, and the bending of fuselage structures

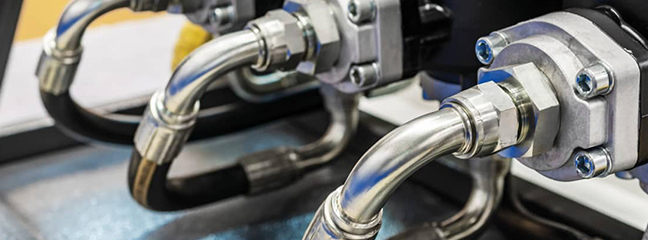

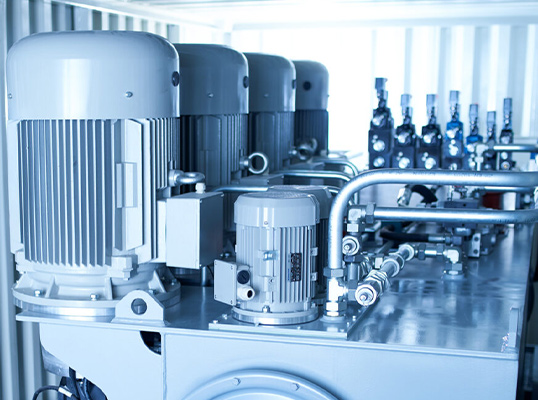

Hydraulics

Specializing in the production of automotive exhaust systems, chassis parts and other core components

Ship Building

Bending fuel pipes, hydraulic pipes, cooling water pipes, etc. of ships

Medical

Used to manufacture surgical instruments, vascular stents and other precision instruments

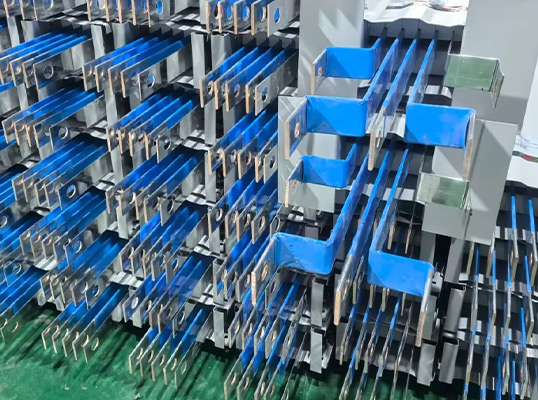

Busbars

Bend copper or aluminum busbars to make compact internal connectors of distribution cabinets

Our Advantages

25Year

Industry Experience

4

Main Products

30+

Multiple Patent Approvals

30+

Professiona R&D Team

60+

Sold In Over 60 Countries

Faq

We have sorted out some frequently raised questions by users, hoping to help you find the answers quickly.

2. Determine the outer diameter and wall thickness of the pipe.

3. Determine the bending diameter again.

4. Determine the appropriate model.

5. Determine the machine price and mold price.

Need to know more service details?

Our professional team is always ready to provide you with detailed consultation and solutions. Fill out the form or contact us directly to get a customized service plan.

heshunchenyi@163.com

Phone

0512-58622076

Service Time

7× 24-hour all-weather service

Contact Us

Certificate

CE Forming Machine

CE Pipe Bender

ISO

Beveling Machine

Cutting Machine

-

Contact